How to place a barcode on a product

How to place a barcode on a product is a common question on the internet. Actually, two types of barcodes must be placed on a product; The first is the product barcode that goes on the individual product and is called EAN-13; The second is the barcode of the box for transportation and distribution where many units of the same product are placed and which is called DUN-14.

First of all, it must be noted that this article has been written by a human being with more than forty years of experience in the commercial coding sector and not by artificial intelligence (oxymoron).

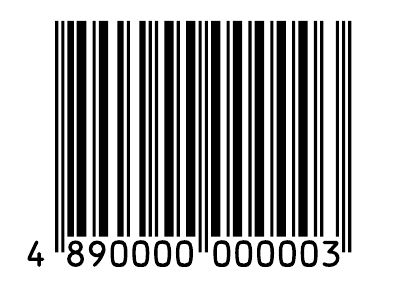

The universal EAN-13 product barcode

The EAN (European Article Number) barcode is a global standard used to identify products in retail. Placing the barcode correctly on the product box is essential to facilitate an efficient point-of-sale scanning process and improve inventory management accuracy.

OFFICIAL HONG KONG GS1 EAN-13 BARCODE (PREFIX 489)

Steps to place an EAN barcode on the product

1. Barcode generation

Use a software or online service to generate the EAN barcode. Make sure the generated code is unique for each product.

2. Selection of the place in the product

Choose a location on the product where the barcode is easily visible and accessible for scanning. The bottom right or top right of the product are common locations.

3. Size and resolution

Adjust the barcode size according to standard guidelines. Make sure the resolution is sufficient so that it can be scanned easily without errors.

4. Contrast and color

The barcode must have adequate contrast with the background of the box. It is recommended to use dark colors for the barcode on a light background and vice versa.

5. Barcode protection

Consider using laminates or coatings to protect the barcode from damage during shipping or storage.

6. Additional information

In addition to the barcode, the box must contain human-readable information such as the product name, description, price, and other relevant information.

7. Local and international regulations

Be sure to comply with local and international regulations regarding barcode placement and format.

8. Scanner tests

Before mass production, scan the barcode to ensure it can be easily read by point-of-sale scanning devices.

9. Conclusion

Proper placement of the EAN barcode on a product is essential to optimize efficiency in the supply chain and improve the customer experience at the point of sale. By following these steps, you can ensure correct product identification and facilitate inventory management, thus contributing to commercial success.

THE OFFICIAL BARCODE FOR RETAIL IS THE EAN-13

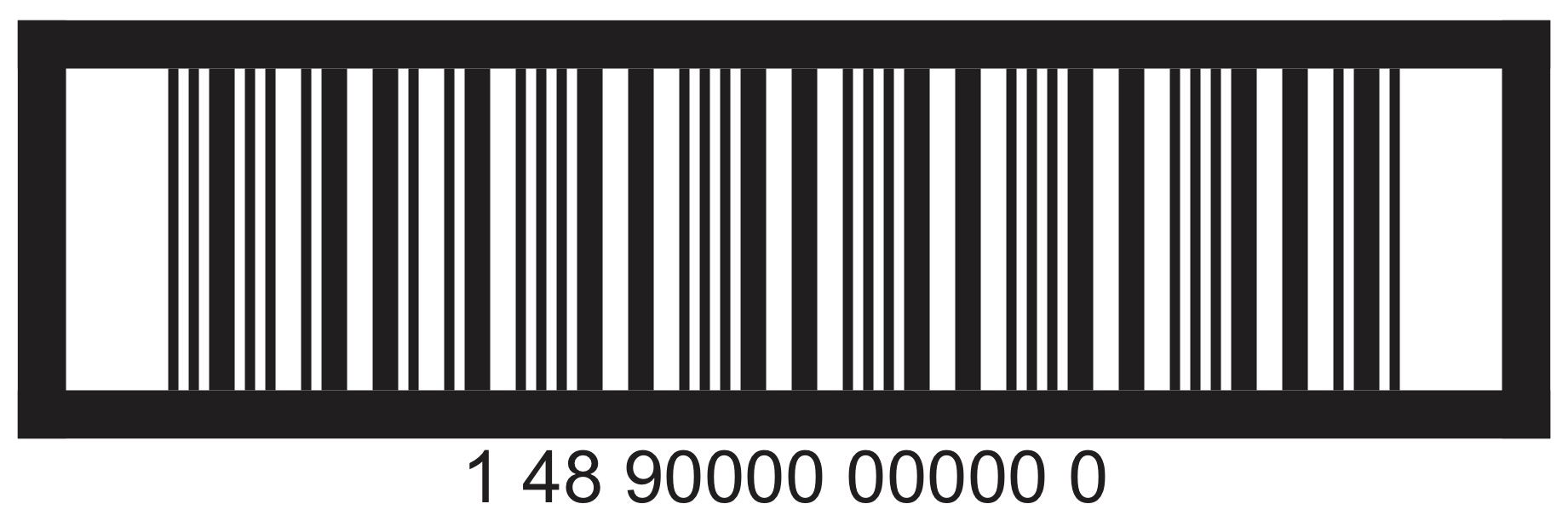

The DUN-14 barcode

Placing the DUN-14 barcode on the shipping box of a product

The DUN-14 (Distribution Unit Number) barcode is used to identify shipping boxes or logistics units containing multiple individual products. Its correct placement in the transport box is crucial to facilitate inventory management, efficient distribution and logistical tracking.

OFFICIAL HONG KONG GS1 DUN-14 BARCODE (PREFIX 489)

Steps to place a DUN-14 barcode on the shipping box

1. Barcode generation

Use specialized software or an online service to generate the DUN-14 barcode. Make sure each shipping box has a unique code.

2. Positioning in the box

The DUN-14 barcode should be placed in an easily visible location on the shipping box. The outside of the box, on the side or on the top, is recommended.

3. Size and resolution

Adjusts the barcode size to standard specifications. The resolution must be sufficient to ensure an accurate reading.

4. Contrast and color

Make sure the barcode has adequate contrast to the background of the box. Use dark colors on light backgrounds or vice versa for easy reading.

5. Additional information

Along with the DUN-14 barcode, it includes human-readable information, such as the detailed contents of the transport box, the number of units and any other information relevant to logistics management.

6. Barcode protection

Consider using protective laminates or coatings to safeguard the barcode from possible damage during shipping and handling.

7. Regulations and standards

Complies with local and international regulations governing the placement and formatting of the DUN-14 barcode on shipping boxes.

8. Scanner tests

Perform scan tests before mass production to ensure that the barcode can be easily read by scanning devices used in the supply chain.

9. Conclusion

Proper placement of the DUN-14 barcode on the shipping box is essential for efficient logistics management and accurate tracking of products throughout the supply chain. By following these steps, a unique and reliable identification of logistics units is guaranteed, thus facilitating the handling, distribution and storage of products.

4/F, Cyberport 3, 100 Cyberport Rd, Telegraph Bay, Hong Kong

ONLY ONLINE SALES!

Please, click here to contact us via WhatsApp